Page 684 - CarrLaneCatalog_2019ed-c.pdf

P. 684

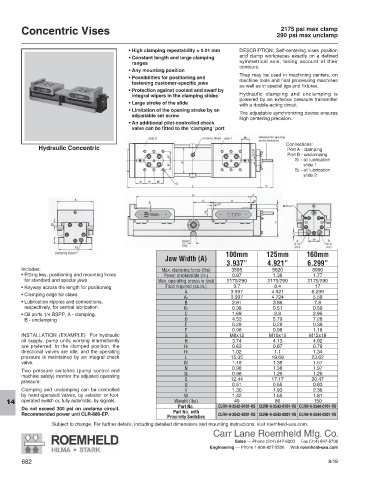

Concentric Vises 2175 psi max clamp

290 psi max unclamp

• High clamping repeatability ± 0.01 mm DESCRIPTION: Self-centering vises position

• Constant length and large clamping and clamp workpieces exactly on a defined

ranges symmetrical axis, taking account of their

contours.

• Any mounting position

They may be used in machining centers, on

• Possibilities for positioning and

fastening customer-specific jaws machine tools and final processing machines

as well as in special jigs and fixtures.

• Protection against coolant and swarf by

Hydraulic clamping and unclamping is

integral wipers in the clamping slides

powered by an external pressure transmitter

• Large stroke of the slide

with a double-acting circuit.

• Limitation of the opening stroke by an

adjustable set screw The adjustable synchronizing device ensures

high centering precision.

• An additional pilot-controlled check

valve can be fitted to the ‘clamping’ port

Connections:

Hydraulic Concentric Port A - clamping

Port B - unclamping

S1 - oil lubrication

slide 1

S2 - oil lubrication

slide 2

100mm 125mm 160mm

Jaw Width (A)

3.937” 4.921” 6.299”

Includes: Max. clamping force (lbs) 3595 5620 8990

• Fitting key, positioning and mounting holes Power stroke/slide (in.) 0.87 1.38 1.77

for standard and special jaws Max. operating pressure (psi) 2175/290 2175/290 2175/290

• Keyway across the length for positioning Fluid required (cu.in.) 3.7 8.4 17

A 3.937 4.921 6.299

• Clamping edge for claws

A1 3.937 4.724 5.59

• Lubrication nipples and connections, B 2.91 3.86 7.8

respectively, for central lubrication. B1 0.39 0.51 0.59

• Oil ports 1/4 BSPP, A - clamping, C 1.69 2.8 2.95

B - unclamping D 4.53 5.79 7.28

E 0.28 0.28 0.39

F 0.98 0.98 1.18

INSTALLATION (EXAMPLE) For hydraulic G M8x12 M10x15 M12x18

oil supply, pump units working intermittently H 3.74 4.13 4.92

are preferred. In the clamped position, the H1 0.63 0.67 0.79

directional valves are idle, and the operating H1 1.02 1.1 1.34

pressure is maintained by an integral check L 15.35 19.69 23.62

valve. M 1.18 1.38 1.57

N 0.98 1.38 1.97

Two pressure switches (pump control and

machine safety) monitor the adjusted operating N1 0.98 1.26 1.26

pressure. S 12.44 17.17 20.47

U 0.51 0.55 0.63

Clamping and unclamping can be controlled V 1.30 1.93 2.36

by hand-operated valves, by selector or foot- W 1.42 1.65 1.81

operated switch or, fully automatic, by signals. Weight (lbs) 49 86 150

14

Part No. CLRH-9-3542-0101-VS CLRH-9-3543-0101-VS CLRH-9-3544-0101-VS

Do not exceed 300 psi on unclamp circuit.

Recommended power unit CLR-886-EP. Part No. with CLRH-9-3542-0201-VS CLRH-9-3543-0201-VS CLRH-9-3544-0201-VS

Proximity Switches

Subject to change. For further details, including detailed dimensions and mounting instructions, visit roemheld-usa.com.

Carr Lane Roemheld Mfg. Co.

Sales — Phone (314) 647-6200 Fax (314) 647-5736

Engineering — Phone 1-800-827-2526 Web roemheld-usa.com

682 8/18