Page 128 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 128

112 Applied Process Design for Chemical and Petrochemical Plants

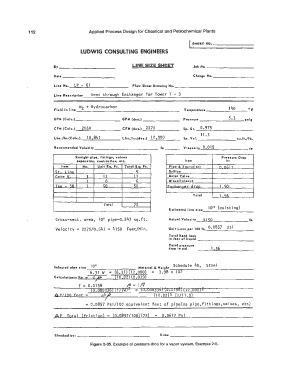

I SHEET NO.--------

LUDWIG CONSULTING ENGINEERS

By __ LINE SIZE SHEET

Date----------- Char9e Ha, _

Line Ha, LP - 61 Flciw Shut Drawl,119 Na. _

L In• Dea cri ptl on __ V_e:...n_t.:._t:...h_r_o_u...::g:...h_E_x_c_ha---' n g � e-r_f_o_r_T_o_w_e_r_T_-_...:3:.__ _

N2 + Hydrocarbon

140 __ F

Fluid in lin•--------------------- Temperature _;_.:....:.._ 0

GPM (Cale,) GPM (du,)------- Pressur• 5_ . :... 3 __ p1i9

CFM (Calc,) __ 2_0_.6-=0 CFM (du,) _2_2_7_0 _ Sp. Gr. 0.975

11.3

Lbs,/hr.(Calc.) __ 1..:.0..i...;:...84...c...;.. 1 Lb1,/hr.(des,) 12, 000 Sp, Val, cu.lt,/11,,

Recammended Velocity------------- fp --- Vi 1ca1 itY._o.,:. . _0_ 1 9:::__ cp

Straight pipe, fitting•, valve• P re1aure Drop

exponslon, contraction, etc. Item In•

Item Mo, Unit E q, Ft. Tata I E q, Ft. Pipe & Equivalent n n&.,17

C,t- I in<> i; Orifice

,-�,-., \I 1 11 11 Matar Valve

1 6 6 Ml 1cellaneou1

T<><> - 4-n 1 en so l'v.-h�"�"'r rlrnn 1 i:;n

Total 1- t;F,

Tatol 72

E atlmated lln• ai:ae 10 11 (existing) _

Cross-sect, area, 10 11 pipe=0,547 sq.ft. Actuol V eloclty _ _,41.JJ�SwDc__ fp

__

Velocity= 2270/0.547 = 4150 Feet/Min, Unit Lass per 100 ft._o_._0_8_57 p_s_i _

Tatal head 1011

In fHt af liquid -----------

Total pre, sure

drap in psi __ -..:cl...:c•..::.5-=.6 _

Selected pipe alu 1 O" Moterlal & Weight Schedu 1 e 40, S tee 1

6.31 W (6.31) (12,000) 3,98 x 10

,,

Calculatlana:Re = d � (I0,02)l0.019)

f = o. o 1 58 I'? = 1 ;V

(o.000336)(f)(w)2 - (o.000336)(0.0158)(12,000)2

l

= 0.0857 Psi/100 equivalent feet of plpe(as pipe,fittings,valves, etc)

AP Total (friction)= (0.0857/100)(72) 0.0617 Psi

Checked by: _ Cote:-----------------

Figure 2-35. Example of pressure drop for a vapor system, Example 2-8.