Page 283 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 283

Mechanical Separations 253

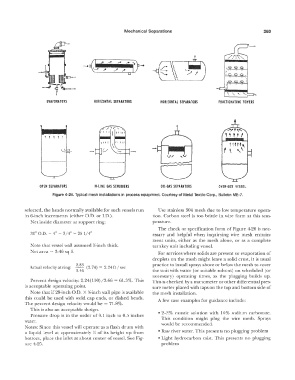

EVAPORATO�S HORIZONTAL SEPARATORS HORIZONTAL SEPARATORS FRACTIONATIN6 rDWERS

H f Ir I I 11 111 I, ' , ,

'

...,,. r' r »;

f11th,

�--

OPEN SEPARATORS IN-LINE GAS SCRUBBERS Oil-GAS SEPARATORS OVER-SIZE VESSEL

Figure 4-24. Typical mesh installations in process equipment. Courtesy of Metal Textile Corp., Bulletin ME-7.

selected, the heads normally available for such vessels run Use stainless 304 mesh due to low temperature opera-

in 6-inch increments ( either O.D. or I.D.). tion. Carbon steel is too brittle in wire form at this tem-

Net inside diameter at support ring: perature.

The check or specification form of Figure 4-2fi is nec-

30" O.D. - 4" - 3/4" = 25 1/4" essary and helpful when inquiry.ing wire mesh entrain-

ment units, either as the mesh alone, or as a complete

Note that vessel wall assumed %-inch thick. turnkey unit including vessel.

Net area = 3.46 sq ft For services where solids are present or evaporation of

droplets on the mesh might leave a solid crust, it is usual

2 83 practice to install sprays above or below the mesh to cover

Actual velocity at ring: · (2. 74) = 2. 24 ft/ sec

3.46 the unit with water (or suitable solvent) on scheduled (or

necessary) operating times, as the plugging builds up.

Percent design velocity: 2.24(100)/3.66 = 61.3%. This This is checked by a manometer or other differential pres-

is acceptable operating point. sure meter placed with taps on the top and bottom side of

Note that if 28-inch O.D. X %-inch wall pipe is available the mesh installation.

this could be used with weld cap ends, or dished heads. A few case examples for guidance include:

The percent design velocity would be = 71.8%.

This is also an acceptable design.

Pressure drop is in the order of 0.1 inch to 0.5 inches • 2-3% caustic solution with 10% sodium carbonate.

water. This condition might plug the wire mesh. Sprays

would be recommended.

Notes: Since this vessel will operate as a flash drum with

a iiquid level at approximately Yi of its height up from • Raw river water. This presents no plugging problem

bottom, place the inlet at about center of vessel. See Fig- • Light hydrocarbon mist. This presents no plugging

ure 4-25. problem