Page 338 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 338

306 Applied Process Design for Chemical and Petrochemical Plants

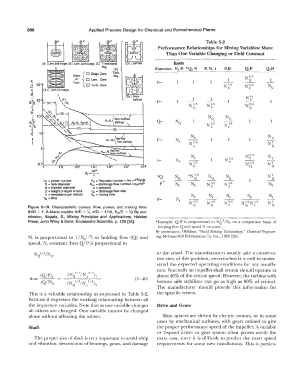

�-�� Performance Relationships for Mixing Variables: More

Table 5-2

Than One Variable Changing or Held Constant

(A,) �� : ··· sta . · ;: � siti:Reg ( Basis

,··=

;,i..

gn. (BJ Lam. with stagn. (CJ (D • l Baffled Function N, D *Q,N P,N, t P,D Q,P Q,D

{

State D Stagn. Zone N s;,1

of D Lam. Zone Q

":= Flow N-

i,! 10' D Turb. Zone ,-, N 1;3 N 3/4 NQ

p

p

Iii (Az) lam.nostagn. : I

i � ' -�'-=:.._�

\ (D2) Non- Nt4

\11l

o!( 1Q3 (A)-! ,,·R, baffled D- p

�11:

1 �.,) L .: ---------------7---- N 1/3 Nl/5 N3;,1

p

Q

Q

(BJ I

k

1'\

• 102 ��,:.

NQ

t� 7 -i-,-� i M R {Non-baffled Q- NQ N3;s N 1/3

�� ..).. � ,{1')1__!1,, � ,_S_Ei �� :

w' Baffled

IQ '\. � [CJ-----j_(D)-----1 p I'

� 10 � ' �� .. �,.�---------:--7-----i

[Baffled NP Np

N,-R, \_ Non-baffled N s/s N3

q Q

NP N 3/1 NP

p

t- NP N � 3

0. ,,'----L....,..L--- , '=-02�--,- , 0.,..3�--,c-!o'""•---,,""o,...-----,,c:!os N5;3 N5!4 N2

Q

Q

Q

nd 2

R,=-v-

*Q NQ *N5;3 NQ NQ N3

Q

Q

2

Np = power number R 0 = Reynolds number = No = d np/µ

0 = tank diameter Nqo = discharge flow number= q,lnd 3 p NP Nr N3;s Nl/3 NP

d = impeller diameter p = pressure p p

Z = height of liquid in tank q 0 = discharge flow rate

n = revolutions per minute 0m = mixing time NF NF NF NF N,

T1,1 =time F- NF

N4;3 N4/5 N!"3 N 112N 112 N2

Figure 5-19. Characteristic curves: flow, power, and mixing time. Q Q Q p Q

(H/D = 1, 8-blade paddle H/D = �. d/D = 1/10, Hc,ID = �) By per-

mission, Nagata, S., Mixing Principles and Applications, Halsted

3

Press, John Wiley & Sons, Kodasnsha Scientific. p. 125 [34). *Example: Q/P is proportional to N({ /Np on a comparison basis of

keeping flow Q and speed N constant.

By permission, Oldshue, "Fluid Mixing Technology," Chemical Engineer-

N, is proportional to l/N/13; or holding flow (Q) and ing, McGraw-Hill Publications Co. Inc., 1983 [29].

speed, N, constant then Q/P is proportional to

to the vessel. The manufacturers usually take a conserva-

tive view of this problem, nevertheless it is well to under-

stand the expected operating conditions for any installa-

tion. Normally an impeller-shaft system should operate at

(Q/P)1 (N 5/3'/N 3/4) I about 40% of the critical speed. However, the turbine with

p

l Q

thus --- (5-40)

bottom side stabilizer can go as high as 80% of critical.

The manufacturer should provide this information for

This is a valuable relationship as expressed in Table 5-2, the specific system.

because it expresses the working relationship between all

the important variables. Note that as one variable changes Drive and Gears

all others are changed. One variable cannot be changed

alone without affecting the others. Most mixers are driven by electric motors, or in some

cases by mechanical turbines, with gears ratioed to give

Shaft the proper performance speed of the impeller. A variable

or 2-speed driver or gear system often proves worth the

The proper size of shafi: is very important to avoid whip extra cost, since it is difficult to predict the exact speed

and vibration, destruction of bearings, gears, and damage requirements for some new installations. This is particu-